Diving cylinder

A diving cylinder, scuba tank or diving tank is a gas cylinder used to store and transport high pressure breathing gas as a component of a scuba set. It provides gas to the scuba diver through the demand valve of a diving regulator.

Diving cylinders typically have an internal volume of between 3 and 18 litres (0.11 and 0.64 cu ft) and a maximum pressure rating from 200 to 300 bars (2,900 to 4,400 psi). The internal cylinder volume is also expressed as "water capacity" - the volume of water which could be contained by the cylinder. When pressurised, a cylinder carries a volume of gas greater than its water capacity because gas is compressible. 600 litres (21 cu ft) of gas at atmospheric pressure is compressed into a 3-litre cylinder when it is filled to 200 bar. Cylinders also come in smaller sizes, such as 0.2, 1.5 and 2 litres, however these are not generally used for breathing, instead being used for purposes such as Surface Marker Buoy, drysuit and buoyancy compensator inflation.

Divers use gas cylinders above water for many purposes including storage of gases for oxygen first aid treatment of diving disorders and as part of storage "banks" for diving air compressor stations. They are also used for many purposes not connected to diving. For these applications they are not diving cylinders.

The term "diving cylinder" tends to be used by gas equipment engineers, manufacturers, support professionals, and divers speaking British English. "Scuba tank" or "diving tank" is more often used colloquially by non-professionals and native speakers of American English. The term "oxygen tank" is commonly used by non-divers when referring to diving cylinders; however, this is a misnomer. These cylinders typically contain (atmospheric) breathing air, or an oxygen-enriched air mix. They rarely contain pure oxygen, except when used for rebreather diving, shallow decompression stops in technical diving or for oxygen therapy. Breathing oxygen at depths greater than 40 feet (12 m) can result in oxygen toxicity, a highly dangerous condition that can trigger seizures and thus lead to drowning.

Contents |

Parts of a cylinder

The diving cylinder consists of several parts:

The pressure vessel

The pressure vessel is normally made of cold-extruded aluminium or forged steel. An especially common cylinder available at tropical dive resorts is an "aluminium-80" which is an aluminium cylinder with an internal volume of 0.39 cubic feet (11 L) rated to hold about 80 cubic feet (2,300 L) of atmospheric pressure gas at its rated pressure of 3,000 psi (210 bar). Aluminium cylinders are also often used where divers carry many cylinders, such as in technical diving in warm water where the dive suit does not provide much buoyancy, because the greater buoyancy of aluminium cylinders reduces the extra buoyancy the diver would need to achieve neutral buoyancy. They are also preferred when carried as "sidemount" or "sling" cylinders as the near neutral buoyancy allows them to hang comfotably along the sides of the diver's body, without disturbing trim, and can be handed off to another diver with a minimal effect on buoyancy. In cold water diving, where a diver wearing a highly buoyant thermally insulating dive suit has a large excess of buoyancy, steel cylinders are often used because they are denser than aluminium cylinders. Kevlar wrapped composite cylinders are used in fire fighting breathing apparatus and oxygen first aid equipment, but are rarely used for diving, due to their high positive buoyancy.

The aluminium alloys used for diving cylinders are 6061 and 6351. 6351 alloy is subject to sustained stress cracking and cylinders manufatured of this alloy should be periodically eddy current tested according to national legislation and manufacturer's recommendations.

The neck of the cylinder is internally threaded to fit a cylinder valve. There are several standards for neck threads , these include:

- Taper thread (17E) [1], which is sealed with thread tape and torqued to between 120 and 150 N.m on steel cylinders, and 75 to 140 N.m on aluminium cylinders [2]

- M25x2 parallel thread , which is sealed by an O-ring and torqued to 100 to 130 N.m on steel, and 95 to 130 N.m on aluminium cylinders[2]

- M18x1.5 parallel thread , which is sealed by an O-ring, and torqued to 100 to 130 N.m on steel cylinders, and 85 to 100 N.m on aluminium cylinders[2]

- 3/4"x14 BSP[3]

- 3/4"x14 NGS (NPSM) sealed by an O-ring, torqued to 40 ft.lbf on aluminium cylinders[4]

- 3/4"x16 UNF, sealed by an O-ring, torqued to 40 ft.lbf on aluminium cylinders[4]

The shoulder of the cylinder carries stamp markings providing required information about the cylinder [5]

The cylinder valve

- the pillar valve or cylinder valve is the point at which the pressure vessel connects to the diving regulator. The purpose of the pillar valve is to control gas flow to and from the pressure vessel and to form a seal with the regulator. Some countries require that the pillar valve includes a burst disk, a type of pressure 'fuse', that will fail before the pressure vessel fails in the event of over pressurization.

- a rubber o-ring forms a seal between the metal of the pillar valve and the metal of the diving regulator. Fluoroelastomer (i.e. "viton") o-rings are used with cylinders storing oxygen-rich gas mixtures to reduce the risk of fire.

Optional accessories

Types of cylinder valve

- The most commonly used cylinder valve type is the single outlet plain valve, sometimes known as a "K" valve[6], which allows connection of a single regulator, and has no reserve funvction. It simply opens to allow gas flow, or closes to shut it off. Several configurations are used, with options of DIN or A-clamp connection, and vertical ir transverse spindle arrangements. The valve is operated by turning a knob, usually rubber or plastic, which affords a comfortable grip. Several turns are required to fully open the valves. Some DIN valves are convertable to A-clamp by use of an insert which is screwed into the opening.

- Y and H cylinder valves have two outlets, each with its own valve, allowing two regulators to be connected to the cylinder. If one regulator "freeflows", which is a common failure mode, or ices up, which can happen in water below about 5°C, its valve can be closed and the cylinder breathed from the regulator connected to the other valve. The difference between an H valve and a Y valve is that the Y valve body splits into two posts roughly 90° to each other and 45° from the vertical axis, looking like a Y, while an H valve is usually assembled from a valve designed as part of a manifold sytem with an additional valve post connected to the manifold socket, with the valve posts parallel and vertical, which looks a bit like an H.

- Reserve lever or "J-valve" (obsolescent). Until the 1970s, when submersible pressure gauges on regulators came into common use, diving cylinders often used a mechanical reserve mechanism to indicate to the diver that the cylinder was nearly empty. The gas supply was automatically cut-off when the gas pressure reached the reserve pressure. To release the reserve, the diver pulled down on a rod that ran along the side of the tank and which activated a lever on the valve. The diver would then finish the dive before the reserve (typically 300 pounds per square inch (21 bar)) was consumed. On occasion, divers would inadvertently trigger the mechanism while donning gear or performing a movement underwater and, not realizing that the reserve had already been accessed, could find themselves out of air at depth with no warning whatsoever. The J-valve got its name from being item number J in one of the first scuba equipment manufacturer catalogs. The standard non-reserve yoke valve at the time was item K, and is often still referred to as a K-valve.[6] J-valves are still occasionally used by professional divers in zero visibility, where the SPG can not be read.

- Less common in the 1950s thru 1970s was an R-valve which was equipped with a restriction that caused breathing to become difficult as the tank neared exhaustion, but that would allow less restricted breathing if the diver began to ascend and the ambient water pressure lessened, providing a larger pressure differential over the orifice. It was never particularly popular because, were it necessary for the diver to descend (as is often necessary in cave and wreck diving, breathing would become progressively more difficult as the diver went deeper, eventually becoming impossible until the diver could begin his or her ascent.[6]

Manifolds

A cylinder manifold is a tube which connects two cylinders together so that the contents of both can be supplied to one or more regulators. There are three commonly used configurations of manifold:

- The earliest type is a tube with a connector on each end which is attached to the cylinder valve outlet, and an outlet connection in the middle, to which the regulator is attached. A variation on this pattern includes a reserve valve at the outlet connector. The cylinders are isolated from the manifold when closed, and the manifold can be attached or disconnected while the cylinders are pressurised.

- More recently, manifolds have become available which connect the cylinders on the cylinder side of the valve, leaving the outlet connection of the cylinder valve available for connection of a regulator. This means that the connection cannot be made or broken while the cylinders are pressurised, as there is no valve to isolate the manifold from the interior of the cylinder. This apparent inconvenience allows a regulator to be connected to each cylinder, and isolated from the internal pressure independently, which allows a malfunctioning regulator on one cylinder to be isolated while still allowing the regulator on the other cylinder access to all the gas in both cylinders.

- These manifolds may be plain or may include an isolation valve in the manifold, which allows the contents of the cylinders to be isolated from each other. This allows the contents of one cylinder to be isolated and secured for the diver if a leak at the cylinder neck thread, manifold connection, or burst disk on the other cylinder causes its contents to be lost.

A relatively uncommon manifold system is a connection which screws directly into the neck threads of both cylinders, and has a single valve to release gas to a connector for a regulator. These manifolds can include a reserve valve, either in the main valve or at one cylinder. This system is mainly of historical interest.[6]

Cylinder bands

Cylinder bands are straps, usually of stainless steel, which are used to clamp two cylinders together as a twin set. The cylinders may be manifolded or independent. It is usual to use a cylinder band near the top of the cylinder, just below the shoulders, and one lower down. The standard distance beween centrelines for bolting to a backplate is 11 inches (280 mm).

Cylinder boot

A cylinder boot is a hard rubber or plastic cover which fits over the base of a diving cylinder to protect the paint from abrasion and impact, to protect the surface the cylinder stands on from impact with the cylinder, and in the case of round bottomed cylinders, to allow the cylinder to stand upright on its base.

Cylinder net

A cylinder net is a tubular net which is stretched over a cylinder and tied on at top and bottom. The function is to protect the paintwork from scratching, and on booted cylinders it also helps drain the surface between the boot and cylinder, which reduces corrosion problems under the boot. Mesh size is usually about 6 millimetres (0.24 in). Some divers will not use boots or nets as they can snag more easily than a bare cylinder and constitute an entrapment hazard in some enironments sich as caves and the interior of wrecks.

Cylinder handle

A cylinder handle may be fitted, usually clamped to the neck, to conveniently carry the cylinder. This can also increase the risk of snagging in an enclosed environment.

Cylinder capacity

There are two commonly used conventions for describing the capacity of a diving cylinder. One is based on the internal volume of the cylinder. The other is based on nominal volume of gas stored.

Internal volume

The internal volume is commonly quoted in most countries. It can be measured easily by filling the cylinder with fresh water. This has resulted in the term 'water capacity' (WC) which is often marked on the cylinder shoulder. It's almost always expressed as a volume but sometimes as weight of the water. Fresh water has a density close to one kilogram per litre so the numerical values will be similar.

The usual units are:

- Volume in litres

- Weight in kilograms

- Pressure in bar.

Nominal volume of gas stored

The nominal volume of gas stored is commonly quoted in the USA. It's a measure of the volume of gas that can be released from the cylinder at atmospheric pressure. Terms used for the volume include 'free gas' or 'free gas equivalent'. It depends on the internal volume and the working pressure of a cylinder. If the working pressure is higher, the cylinder will store more gas for the same volume.

The working pressure is not neccessarily the same as the actual pressure used. Some cylinders are permitted to exceed the nominal working pressure by 10% and this is indicated by a '+' symbol. This extra pressure allowance is dependant on the cylinder passing the appropriate periodical hydrostatic test and is not generally valid for US cylinders exported to countries with differing standards.

For example, common Al80 cylinder is an aluminum cylinder which has a nominal 'free gas' volume of 80 cubic feet (2,300 L) when pressurised to 3,000 pounds per square inch (210 bar). It has an internal volume of 10.94 litres (0.386 cu ft).

Types of pillar valve

There are three types of pillar valve in general use for Scuba cylinders containing air:

- A-clamp or yoke - the connection on the regulator surrounds the valve pillar and presses the output O-ring of the pillar valve against the input seat of the regulator. The yoke is screwed down snug by hand (over-tightening can make the yoke impossible to remove later without tools) and the seal is created by pressure when the valve is opened. This type is simple, cheap and very widely used worldwide. It has a maximum pressure rating of 232 bar and the weakest part of the seal, the O-ring, is not well protected from over-pressurisation.

- 232 bar DIN (5-thread, G5/8) - the regulator screws into the pillar valve trapping the O-ring securely. These are more reliable than A-clamps because the O-ring is well protected, but many countries do not use DIN fittings widely on compressors, or cylinders which have DIN fittings, so a European diver with a DIN system abroad in many places will need to take an adaptor.

- 300 bar DIN (7-thread, G5/8) - these are similar to 5-thread DIN fitting but are rated to 300 bar working pressures. The 300 bar pressures are common in European diving and in US cave diving, but their acceptance in U.S. sport diving has been hampered by the fact that United States Department of Transportation rules presently prohibit the transport of metal scuba cylinders on public roads with pressures above about 230 bar, even if the cylinders and air delivery systems have been rated for these pressures by the American agencies which oversee cylinder testing and equipment compatibility for SCUBA (Occupational Safety and Health Administration and Compressed Gas Association).

Adaptors are available to allow connection of DIN regulators to yoke cylinder valves (A-clamp or yoke adaptor), and to connect yoke regulators to DIN cylinder valves. (plug adaptors and block adaptors)

There are also cylinder valves for Scuba cylinders containing gases other than air:

- The new European Norm EN 144-3:2003 introduced a new type of valve, similar to existing 232 bar or 300 bar DIN valves, however, with a metric M 26×2 fitting on both the cylinder and the regulator. These are to be used for breathing gas with oxygen content above that normally found in natural air in the Earth's atmosphere (i.e. 22–100%). From August 2008, these shall be required for all diving equipment used with nitrox or pure oxygen. The idea behind this new standard is to prevent a rich mixture being filled to a cylinder that is not oxygen clean. However even with use of the new system there still remains nothing except human procedural care to ensure that a cylinder with a new valve remains oxygen-clean - which is exactly how the current system works.

- A male thread cylinder valve was supplied with some Dräger semi-closed circuit recreational rebreathers (Dräger Ray) for use with nitrox mixtures.

Applications and configurations of diving cylinders

Divers may carry one cylinder or multiples, depending on the requirements of the dive. Where diving takes place in low risk areas, where the diver may safely make a free ascent, or where a buddy is available to provide an alternative air supply in an emergency, recreational divers usually carry only one cylinder. An example of this type is coral reef diving where it is possible to do an interesting dive without going deep or needing decompression. Where diving risks are higher, for example where the visibility is low or when recreational divers do deeper or decompression diving, divers routinely carry more than one gas source. An example of this type is north European diving where the temperature is often less than 15 °C (60 °F) and visibility less than 10 m (33 ft) and many interesting dive sites are shipwrecks in deeper water on the sea bed.

Diving cylinders may serve different purposes. One or two cylinders may be used as a primary breathing source which is intended to be breathed from for most of the dive. A smaller cylinder carried in addition to a larger cylinder is called a "pony bottle". A cylinder to be used purely as an independent safety reserve is called a "bailout bottle". A pony bottle is commonly used as a bailout bottle, but this would depend on the time required to surface.

Divers doing technical diving often carry different gases, each in a separate cylinder, for each phase of the dive:

- "travel gas" is used during the descent and ascent. It is typically air or nitrox with an oxygen content between 21% and 40%. Travel gas is needed when the bottom gas is hypoxic and therefore is unsafe to breathe in shallow water.

- "bottom gas" is only breathed at depth. It is typically a helium-based gas which is low in oxygen (below 21%) or hypoxic (below 17%).

- "deco gas" is used at the decompression stops and is generally a nitrox with a high oxygen content, or pure oxygen, to accelerate decompression.

- a "stage" is a cylinder holding reserve, travel or deco gas. They are usually carried "side slung", clipped on either side of the diver to the harness of the backplate and wing or buoyancy compensator, rather than on the back. Commonly divers use aluminium stage cylinders because they are nearly neutrally buoyant in water and can be removed underwater with less effect on the diver's overall buoyancy.

Rebreathers may use internal cylinders:

- oxygen rebreathers have an oxygen cylinder

- semi-closed circuit rebreathers have a cylinder which usually contains nitrox or a helium based gas.

- closed circuit rebreathers have an oxygen cylinder and a "diluent" cylinder, which contains air, nitrox or a helium based gas

Rebreathers may also be supplied from "off-board" cylinders, which are not permanently plumbed into the rebreather, but connected to it by a flexible hose and coupling and usually carried side slung. Rebreather divers also often carry a bailout cylinder if the internal diluent cylinder is too small for safe use for bailout.

For safety, divers sometimes carry an additional redundant aqualung (a second scuba tank and scuba valve) to mitigate out-of-air emergencies should the primary breathing source fail. For most common recreational diving (for example dives of 20 m (66 ft) to examine typical coral reefs), such extra equipment is usually not needed or used. This extra cylinder is known as a bail-out cylinder, and may be carried in several ways, and can be any size that can hold enough gas to get the diver safely back to the surface.

Open-circuit

For open-circuit divers, there are several options for the combined cylinder and regulator system:

- Single cylinder or single aqualung: consists of a single large cylinder with one first-stage regulator, and usually two secondary regulator/mouthpieces. This configuration is simple and cheap but it is only a single system: it has no redundancy in case of failure. If the cylinder or first-stage regulator fails, the diver is totally out of air and faces an emergency. All training agencies train divers to rely on a buddy to assist them in this situation. The skill of gas sharing is required at the most basic scuba course. This equipment configuration, although common with entry-level divers and for most sport diving, is not recommended for any dive that is deeper than 30 m (100 ft) or where decompression stops are needed, or where there is an overhead environment (wreck diving, cave diving, or ice diving). Generally, these conditions, because they prevent immediate emergency ascent, may define technical diving.

- Single cylinder with dual regulators: consists of a single large cylinder with two first-stage regulators each with a second stage regulator/mouthpiece. This system is used for recreational diving where cold water makes redundancy required. It is common in continental Europe, especially Germany. The advantage is that a regulator failure can be solved under water to bring the dive to a controlled conclusion without buddy breathing or gas sharing. However, it is hard to reach the valves, so there is some reliance on the dive buddy to help close the valves of the free-flowing regulator quickly.

- Main cylinder plus a small independent cylinder: this configuration uses a larger, main cylinder along with an independent smaller cylinder, often called a "pony". The diver has two independent systems, but the total 'breathing system' is now heavier, more expensive to buy and maintain.

- The pony is typically a 2 to 5 litre cylinder. Its capacity determines the depth of dive and decompression duration for which it provides protection. Ponies are generally fixed to the diver's buoyancy compensator (BC) or main cylinder behind the diver's back. They can also be clipped to the BC at the diver's side or chest. Ponies provided an acceptable emergency supply but are only useful if the diver trains to bail out, i.e. to use one.

- Another type of separate small air source is a hand-held cylinder filled with about 85 litres (0.279 ft) of free air with a diving regulator directly attached, such as the Spare Air.[7] This source provides only a few breaths of gas at depth and is mainly suitable as a shallow water bailout.

- Independent twin set /doubles: this consists of two independent cylinders and two regulators. This system is heavier, more expensive to buy and maintain and more expensive to fill. Also the diver must swap demand valves during dive to preserve a safety reserve of air in each cylinder. If this is not done, then should a cylinder fail the diver may end up having no reserve. Independent twin sets do not work well with air-integrated computers - as they usually only monitor one tank. Many divers feel the complexity of switching regulators periodically to ensure both cylinders are evenly used is offset by the redundancy of two entirely separate breathing supplies. These will normally be mounted as a twin set on the diver's back, but alternatively can be carried in a sidemount configuration where penetration of wrecks or caves requires it.

- Manifolded twin set /doubles with a single regulator: two cylinders are joined at their pillar valves with a manifold but only one regulator is attached to the system. This makes it simple and cheap but means there is no redundant breathing system, only a double gas supply.

- Manifolded twin set /doubles with two regulators: consist of two cylinders with their pillar valves joined with a manifold, with a valve that can isolate the two pillar valves. In the event of a problem with one cylinder the diver may close the isolator valve to preserve gas in the cylinder which has not failed. The pros of this configuration include a large gas supply, no requirement to change regulators underwater, automatic gas supply management, and in most failure situations the diver may close a failed valve or isolate a cylinder in order to leave himself with an emergency supply. On the down side the manifold is another potential point of failure, and there is a danger of losing all air if the manifold valve cannot be closed when a problem occurs. This configuration of cylinders is often used in Technical diving.

- Sling bottles/cylinders: are a configuration of independent cylinder used for technical diving. They are independent cylinders with their own regulators and ase carried clipped to the harness at the side of the diver. Their purpose may be to carry either stage, travel, decompression, or bailout gas while the back mounted cylinder(s) carry bottom gas. Stage cylinders carry gas to extend bottom time, travel gas is used to reach a depth where bottom gas may be safely used if it is hypoxic at the surface, and decompression gas is gas intended to be used during decompression to accelerate the elimination of inert gases. Bailout gas is an emergency supply intended to to be used to surface if the main gas supply is lost.

- Side mount cylinders: are sling cylinders mounted at the diver's side which carry bottom gas when the diver does not carry back mount cylinders. They may be used in conjunction with other sling cylinders where necessary.

Closed-circuit

Diving cylinders are used in closed-circuit diving in two roles:

- As part of the rebreather itself. The rebreather must have at least one source of fresh gas stored in a cylinder; many have two and some have more cylinders. Due to the lower gas consumption of rebreathers, these cylinders typically are smaller than those used for equivalent open-circuit dives. See the main article: rebreather.

- In a bail out system: rebreather divers often carry one or more redundant gas sources should the rebreather fail:

- Open-circuit: a simple diving cylinder and regulator. The number of open-circuit bail outs, their capacity and the breathing gases they contain depend on the depth and decompression needs of the dive. So on a deep, technical rebreather dive, the diver will need a bail out "bottom" gas and a bail out "decompression" gas for use. On such a dive, it is the capacity and duration of the bail out that limits the depth and duration of the dive - not the capacity of the rebreather.

- Closed-circuit: a rebreather containing a diving cylinder and regulator. Using another rebreather as a bail out is possible but uncommon. Although the long duration of rebreathers seems compelling for a bail out, rebreathers are relatively bulky, complex, vulnerable to damage and require more time to start breathing from, than easy-to-use, instantly available, robust and reliable open-circuit equipment.

Gas calculations

Breathing gas endurance

A commonly asked question is 'what is the underwater duration of a particular cylinder?'

There are two parts to this problem:

The cylinder's capacity to store gas

Two features of the cylinder determine its gas carrying capacity:

- working gas pressure : this normally ranges between 200 and 300 bars (2,900 and 4,400 psi)

- internal volume : this normally ranges between 3 litres and 18 litres

To calculate the quantity of gas:

Volume of gas at atmospheric pressure = (cylinder volume) x (cylinder pressure) / (atmospheric pressure)

So a 12 litre cylinder at 232 bar would hold almost 2,784 litres (98.3 cu ft) of air at atmospheric pressure.

In the US and in many diving resorts you might find aluminum cylinders with an internal capacity of 0.39 cubic feet (11 L) filled to 3,000 psi (210 bar); Taking air pressure as 14.7 psi, this gives 0.39 x 3000 / 14.7 = 80 ft³ These cylinders would be described by US convention as "80 cubic foot cylinders", (the common "aluminum-80") as the US normally refers to cylinder capacity as free-air equivalent at its working pressure, rather than the internal volume of the cylinder, which is the measure commonly used in metric countries.

Up to 200 bar the ideal gas law remains valid and the relationship between the pressure, size of the cylinder and gas contained in the cylinder is linear; at higher pressures there is proportionally less gas in the cylinder. A 3 litre, 300 bar cylinder can only carry up to 810 litres (29 cu ft) of atmospheric pressure gas and not the 900 litres expected from the ideal gas law.

Diver gas consumption

There are three factors at work here:

- breathing rate or respiratory minute volume (RMV) of the diver. In normal conditions this will be between 10 and 25 litres per minute (L/min) for recreational divers who are not working hard. At times of extreme high work rate, breathing rates can rise to 95 L/min.[8]

In the UK, a working breathing rate of 40 litres per minute is used for commercial diving, whilst a figure of 50 litres per minute is used for emergencies. (The Association of Diving Contractors)

- time

- ambient pressure: the depth of the dive determines this. The ambient pressure at the surface is 1 bar (15 psi). For every 10 metres (33 ft) in salt water the diver descends, the pressure increases by 1 bar (15 psi). As a diver goes deeper, the breathing gas is delivered at a pressure equal to ambient water pressure. Thus, it requires twice as much mass of gas to fill the same volume (the diver's lungs) at 10 metres (33 ft) as it does at the surface, and three times as much at 20 metres (66 ft). If a given cylinder consumed at a constant rate would last a diver one hour at the surface, it would last 30 minutes at 10 metres (33 ft), 20 minutes at 20 metres (66 ft) and just 15 minutes at 30 metres (98 ft).

To calculate the quantity of gas consumed:

gas consumed = breathing rate × time × ambient pressure

Thus, a diver with a breathing rate of 20 L/min will consume at 30 meters (4 bar) the equivalent of 80 L/min at 1 bar (e.g. at the surface). If this diver only had a 10 litre 200 bar cylinder to breathe from, the gas in the cylinder would be exhausted after 2000/80 = 25 minutes.

Keeping this in mind, it is not hard to see why technical divers who do long deep dives require multiple cylinders or rebreathers.

Breathing time

For metric users:

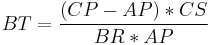

Absolute maximum breathing time (BT) can be calculated as

- BT = available air / rate of consumption

which, using the ideal gas law, is

- BT = (available cylinder pressure × cylinder volume) / (rate of air consumption at surface) × (ambient pressure)

This may be written as

- (1)

with

- BT = Breathing Time (in minutes)

- CP = Cylinder Pressure (in bars)

- CS = Cylinder Size (in liters)

- AP = Ambient Pressure (in bars)

- BR = Breathing Rate (in liters per minute)

AP is deducted from CP, as the quantity of air represented by AP can in practice not be used for breathing by the diver as she needs it to overcome the pressure of the water (AP) when inhaling.

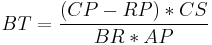

However, in normal diving usage, a reserve is always factored in. The reserve is a proportion of the cylinder pressure which a diver will not expect to use other than in case of emergency. The reserve may be a quarter or a third of the cylinder pressure or it may be a fixed pressure, common examples are 50 bar and 500 psi. The formula above is then modified to give the usable breathing time as

- (2)

where RP is the reserve pressure.

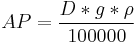

Ambient pressure (AP) is the surrounding water pressure at a given depth and is made up of the sum of the water pressure and the air pressure at the surface. It is calculated as

- (3)

+ atmospheric pressure

+ atmospheric pressure

with

- D = Depth (in meters)

- g = Standard gravity (in meters per second squared)

- ρ = Water Density (in kg per cube meter)

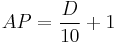

In practical terms, this formula can be approximated by

- (4)

For example (using the first formula (1) for absolute maximum breathing time), a diver at a depth of 15 meters in water with an average density of 1020 kg / m³ (typical salt water), who breathes at a rate of 20 liters per minute, using a dive cylinder of 18 liters pressurized at 200 bars, can breathe for a period of 72 minutes before the cylinder and supply line pressure has fallen so low as to prevent her from inhaling. In most open circuit scuba systems this happens quite suddenly, from a normal breath to the next abnormal breath, a breath which typically cannot be fully drawn. (There is never any difficulty exhaling). In such circumstances there remains air under pressure in the cylinder, but the diver is unable to breathe it. Some of it can be breathed if the diver ascends, and even without ascent, in some systems a bit of air from the cylinder is available to inflate BCD devices even after it no longer has pressure enough to actuate the mouthpiece valve.

Using the same conditions and a reserve of 50 bar, the formula (2) for usable breathing time is worked thus:

- Ambient pressure = water pressure + atmospheric pressure = 15/10 + 1 = 2.5 bar

- Usable air = usable pressure * cylinder capacity = (200-50) * 18 = 2700 liters

- Rate of consumption = surface air consumption * ambient pressure = 20 * 2.5 = 50 liters/min

- Usable breathing time = 2700 liters / 50 liters/min = 54 min

This would give a dive time of 54 min at 15 m before reaching the reserve of 50 bar.

Reserves

It is strongly recommended that a portion of the usable gas of the cylinder be held aside as a safety reserve. The reserve is designed to provide gas for longer than planned decompression stops or to provide time to resolve underwater emergencies.

The size of the reserve depends upon the risks involved during the dive. A deep or decompression dive warrants a greater reserve than a shallow or a no stop dive. In recreational diving for example, it is recommended that the diver plans to surface with a reserve remaining in the cylinder of 500 psi, 50 bar or 25% of the initial capacity, depending of the teaching of the diver training organisation. This is because recreational divers practicing within "no-decompression" limits can normally make a direct ascent in an emergency. On technical dives where a direct ascent is either impossible (due to overhead obstructions) or dangerous (due to the requirement to make decompression stops), divers plan larger margins of safety using the rule of thirds: one third of the gas supply is planned for the outward journey, one third is for the return journey and one third is a safety reserve.

Some training agencies teach the concept of minimum gas and provide a simple calculation that allows a diver to work out an acceptable reserve to get two divers in an emergency to the surface. See DIR diving for more information.

Weight of gas consumed

The loss of the weight of the gas taken from the cylinder makes the cylinder and diver more buoyant. This can be a problem if the diver is unable to remain neutrally buoyant towards the end of the dive because most of the gas has been breathed from the cylinder.

Table showing the buoyancy of diving cylinders in water when empty and full of air.

Assumes 1 litre of air at atmospheric pressure and 10°C weighs 1.25g.[9]

| Cylinder | Air | Weight on land | Buoyancy | |||||

| Material | Volume | Pressure | Volume | Weight | Empty | Full | Empty | Full |

| (litre) | (bar) | (litre) | (kg) | (kg) | (kg) | (kg) | (kg) | |

| Steel | 12 | 200 | 2400 | 3.0 | 16.0 | 19.0 | -1.2 | -4.3 |

| 15 | 200 | 3000 | 3.8 | 20.0 | 23.8 | -1.4 | -5.2 | |

| 16 (XS 130) | 230 | 3680 | 4.7 | 19.5 | 23.9 | -0.9 | -5.3 | |

| 2x7 | 200 | 2800 | 3.5 | 19.5 | 23.0 | -2.0 | -5.6 | |

| 8 | 300 | 2400 | 3.0 | 13.0 | 16.0 | -3.5 | -6.5 | |

| 10 | 300 | 3000 | 3.8 | 17.0 | 20.8 | -4.0 | -7.8 | |

| 2x4 | 300 | 2400 | 3.0 | 15.0 | 18.0 | -4.0 | -7.0 | |

| 2x6 | 300 | 3600 | 4.6 | 21.0 | 25.6 | -5.0 | -9.6 | |

| Aluminium | 9 (AL 63) | 203 | 1826 | 2.3 | 12.2 | 13.5 | +1.8 | -0.5 |

| 11 (AL 80) | 203 | 2247 | 2.8 | 14.4 | 17.2 | +1.8 | -1.1 | |

| 13 (AL100) | 203 | 2584 | 3.2 | 17.1 | 20.3 | +1.4 | -1.7 | |

Filling tanks

Tanks should only be filled with air from diving air compressors or with other breathing gases using gas blending techniques.[10] Both these services should be provided by reliable suppliers such as dive shops. Breathing industrial compressed gases can be lethal because the high pressure increases the effect of any impurities in them.

Special precautions need to be taken with gases other than air:

- oxygen in high concentrations is a major cause of fire and rust.

- oxygen should be very carefully transferred from one tank to another and only ever stored in tanks that are certified and labeled for oxygen use.

- gas mixtures containing proportions of oxygen other than 21% could be extremely dangerous to divers who are unaware of the proportion of oxygen in them. All cylinders should be labeled with their composition.

Contaminated air at depth can be fatal. Common contaminants are: carbon monoxide a by-product of combustion, carbon dioxide a product of metabolism, oil and lubricants from the compressor.[10]

Keeping the cylinder slightly pressurized at all times reduces the possibility of contaminating the inside of the cylinder with corrosive agents, such as sea water, or toxic material, such as oils, poisonous gases, fungi or bacteria.

The blast caused by a sudden release of the gas pressure inside a diving cylinder makes them very dangerous if mismanaged. The greatest risk of explosion exists at filling time and comes from thinning of the walls of the pressure vessel due to corrosion. Another cause of failure is damage or corrosion of the threads and neck of the cylinder where the pillar valve is screwed in. Aluminium cylinders have been observed occasionally to fail explosively, fragmenting the cylinder wall. Steel cylinders usually remain mostly intact, and tend to fail at the neck.

Manufacture and testing

Most countries require tanks to be checked on a regular basis, see gas cylinder. This usually consists of an internal visual inspection and a hydrostatic test.

- In the United States, a visual inspection is NOT required by the USA DOT every year though they do require a hydrostatic every five years. The visual inspection requirement is a diving industry standard based on observations made during a review by the National Underwater Accident Data Center.[11]

- In European Union countries a visual inspection is required every 2.5 years, and a hydrostatic every five years.

- In Norway a hydrostatic (including a visual inspection) is required 3 years after production date, then every 2 years.

- Legislation in Australia requires that cylinders are hydrostatically tested every twelve months, regardless.

- In South Africa a hydrostatic test is required every 4 years, and visual inspection every year. Eddy current testing of neck threads must be done according to the manufacturer's recommendations.[12]

A hydrostatic test involves pressurising the cylinder to its test pressure and measuring its volume before and after the test. A permanent increase in volume above the tolerated level means the cylinder fails the test and should be permanently removed from service.

When a cylinder is manufactured, its specification, including Working Pressure, Test Pressure, Data of Manufacture, Capacity and Weight are stamped on the cylinder. [13]

After a cylinder passes the test, the test date, (or the test expiry date in some countries such as Germany), is punched into the shoulder of the tank for easy verification at fill time. Note: this is a European requirement. There is an international standard for the stamp format [13]

Most compressor operators check these details before filling the cylinder and may refuse to fill non-standard or out-of-test cylinders. Note: this is a European requirement, a requirement of the USA DOT, and a South African requirement.

Safety

Before any cylinder is filled, verification of testing dates and a visual examination for external damage and corrosion are required by law in some jurisdictions[12], and are prudent even if not legally required at other places.

Before use the user should verify the contents of the cylinder and check the function of the cylinder valve. Pressure and gas mixture are critical information for the diver, and the valve should open freely without sticking or leaks from the spindle seals. Sniffing air bled from a cylinder may also reveal unpleasant surprises better left on land than discovered in the water.

Cylinders should not be left standing unattended unless secured[12] so that they can not fall in reasonable foreseeable circumstances as an impact could damage the cylinder valve mechanism, and cocievably fracture the valve at the neck threads. This is more likely with taper thread valves, and when it happens the energy of the compressed gas is released within a second, and can accelerate the cylinder to speeds which can caues severe injury or damage to the surroundings.

A neatly assembled setup, with regulators, gauges, and delicate computers butterflied inside the BCD, or clipped where they will not be walked on, and stowed under the boat bench or secured to a rack, is the practice of a competent diver.

As the scuba set is a life support system, one should not touch a fellow diver's gear, even to move it, without their knowledge and approval.

Full cylinders should not be exposed to temperatures above 65°C[12] and cylinders should not be filled to pressures greater than the developed pressure appropriate to the certified working pressure of the cylinder except by a test station performing a hydrostatic test[12].

Cylinders should be clearly labelled with their current contents. A generic "Nitrox" or "Trimix" label will alert the user that the contents may not be air, and must be analysed before use. In some parts of the world a label is required specifically indicating that the contents are air, and in other places a colour code without additional labels indicates by default that the contents are air.[12]

Cases of lateral epicondylitis are also reported from the handling of diving cylinders.[14]

Gas cylinder colour coding and labeling

European Union

In the European Union gas cylinders may be colour coded according to EN 1098-3. The "shoulder" is the top of the cylinder close to the pillar valve. For mixed gases, the colours can be either bands or "quarters".

- Air has either a white (RAL 9010) top and black (RAL 9005) band on the shoulder, or white (RAL 9010) and black (RAL 9005) "quartered" shoulders.

- Heliox has either a white (RAL 9010) top and brown (RAL 8008) band on the shoulder, or white (RAL 9010) and brown (RAL 8008) "quartered" shoulders.

- Nitrox, like Air, has either a white (RAL 9010) top and black (RAL 9005) band on the shoulder, or white (RAL 9010) and black (RAL 9005) "quartered" shoulders.

- Pure oxygen has a white shoulder (RAL 9010).

- Pure helium has a brown shoulder (RAL 9008).

- Trimix has a white, black and brown segmented shoulder.

Note: As of the end of 2006, the quartered parts is obsolete, and new cylinders are now with the band, and the old system is repainted.

In the European Union breathing gas cylinders must be labeled with their contents. The label should state the type of breathing gas contained by the cylinder.[15]

South Africa

Scuba cylinders are reqired to comply with the colors and markings specified in SANS 10019:2006.[12]

- Cylinder colour is Golden yellow with a French grey shoulder.

- Cylinders containing gases other than air or medical oxygen must have a transparent adhesive label stuck on below the shoulder with the word NITROX or TRIMIX in green and the composition of the gas listed.

- Cylinders containing medical oxygen must be black with a white shoulder.

Worldwide

In many recreational diving settings where air and nitrox are the widely used gases, nitrox cylinders are colour-coded with a green stripe on yellow bottom. The normal colour of aluminium diving cylinders is their natural silver. Steel diving cylinders are often painted, to reduce corrosion, mainly yellow or white to increase visibility. In some industrial cylinder identification colour tables, yellow shoulders means chlorine and more generally within Europe it refers to cylinders with Toxic and/or Corrosive contents; but this is of no significance in SCUBA since gas fittings would not be compatible.

Cylinders that are subject to gas blending with pure oxygen also need an "oxygen service certificate" label indicating they have been prepared for use in an oxygen-rich environment.

References

- ^ International standard ISO 11116-1, First edition 1999

- ^ a b c International standard ISO 13341, Transportable gas cylinders - Fitting of valves to gas cylinders, First edition 1997.

- ^ British Standard 2779

- ^ a b Catalina cylinders, Technical support document, Valving of Scuba (air) cylinders, Nov 2005.

- ^ International Standard ISO 13769, Gas cylinders - Stamp markings. First edition 2002

- ^ a b c d Fred M. Roberts (1963); Basic Scuba: Self contained underwater breathing apparatus: Its operation, maintenance and use, Second edition, Van Nostrand Reinholdt, New York

- ^ "Spare Air". Submersible Systems. 2009-07-07. http://www.spareair.com/. Retrieved 2009-09-19.

- ^ NOAA Diving Manual, 4th Edition CD-ROM prepared and distributed by the National Technical Information Service (NTIS)in partnership with NOAA and Best Publishing Company

- ^ http://www.gasdiving.co.uk/pages/misc/kit/cylinder.htm Gas Diving

- ^ a b Millar IL; Mouldey PG (2008). "Compressed breathing air – the potential for evil from within.". Diving and Hyperbaric Medicine. (South Pacific Underwater Medicine Society) 38: 145–51. http://archive.rubicon-foundation.org/7964. Retrieved 2009-02-28.

- ^ Henderson, NC; Berry, WE; Eiber, RJ; Frink, DW (1970). "Investigation of scuba cylinder corrosion, Phase 1.". National Underwater Accident Data Center Technical Report Number 1 (University of Rhode Island). http://archive.rubicon-foundation.org/9293. Retrieved 2011-09-24.

- ^ a b c d e f g South African National Standard SANS 10019:2008

- ^ a b International standard ISO 13769, 1st Ed.2002-07-01 Gas cylinders - Stamp marking

- ^ Barr, Lori L; Martin, Larry R (1991). "Tank carrier’s lateral epicondylitis: Case reports and a new cause for an old entity". Journal of the South Pacific Underwater Medicine Society 21 (1). http://archive.rubicon-foundation.org/9432. Retrieved 2011-11-21.

- ^ "Identifying Cylinders". BOC UK. 2010. http://www.boconline.co.uk/health/gas_safety/identifying_gas_cylinders/identifying_cylinders.asp. Retrieved 13 November 2011.

- CEN. EN 1089-2:2002 Transportable gas Cylinders, Part 2 - Precautionary labels Superseded by EN ISO 7225:2007.

- CEN. EN 1089-3:2004 Transportable gas Cylinders, Part 3 - Colour coding Current standard.

External links

Media related to [//commons.wikimedia.org/wiki/Category:Diving_cylinders Diving cylinders] at Wikimedia Commons